Fascination About Pressure Washer Sandblaster

Wiki Article

The 5-Minute Rule for Sand Blaster Harbor Freight

Table of ContentsSome Known Incorrect Statements About Sand Blaster Harbor Freight Black Diamond Blasting Sand Things To Know Before You Get ThisThe Single Strategy To Use For Abrasive BlastingNot known Facts About Mobile Sandblasting Near MeThe Buzz on Sandblasting

Nonetheless, in all instances their usage can provide severe risk to operators, such as burns due to projections (with skin or eye lesions), drops as a result of walking on round shot spread on the ground, exposure to dangerous dirts, warmth exhaustion, creation of an eruptive atmosphere, and also direct exposure to extreme sound.Blasting lead-based paint can fill the air with lead fragments which can be unsafe to the nerves. In the United States the Occupational Security and Wellness Administration (OSHA) requireds engineered solutions to possible dangers, however silica sand proceeds to be enabled although the majority of frequently made use of blast headgears are not adequately effective at protecting the blast driver if ambient levels of dust go beyond permitted limits.

Worn-look denims [edit] Numerous customers are ready to pay added for pants that have the appearance of being made use of. To provide the textiles the right used appearance sandblasting is utilized. Sandblasting has the danger of causing silicosis to the workers, and also in Turkey, more than 5,000 workers in the textile sector deal with silicosis, and also 46 people are understood to have actually passed away from it.

3 Easy Facts About Harbor Freight Sand Blaster Shown

's Fair Profession Facility carried out a study among 17 textile firms that showed extremely couple of were mindful of the threats created by manually sandblasting jeans. In 2013, research study claimed that in China some factories generating worn-look jeans are included in different non-compliance with wellness and safety and security policies.Intro This write-up supplies comprehensive details regarding sandblast closets. You will certainly find out just how these sandblast closets are made as well as their materials of building and construction in addition to applications, benefits, and also drawbacks. Read additionally to respond to inquiries like: Just how do sandblast closets function? Why should you choose sandblast closets rather than various other cleansing and also surface area preparation devices? What can sandblast cupboards do? Exactly how can you enhance your production operations with unpleasant blowing up equipment? How are sandblasters made? What are the products of construction? Just how do I define a sandblast cabinet when getting or sending an RFQ? What kinds of abrasives, shot and also blast media are used? Can I deal with, reuse, and reuse utilized abrasives, shot, and blast media? Does the blast media break sandblast cabinet components? And a lot more Sandblast Cabinet from Great Lakes Finishing I.

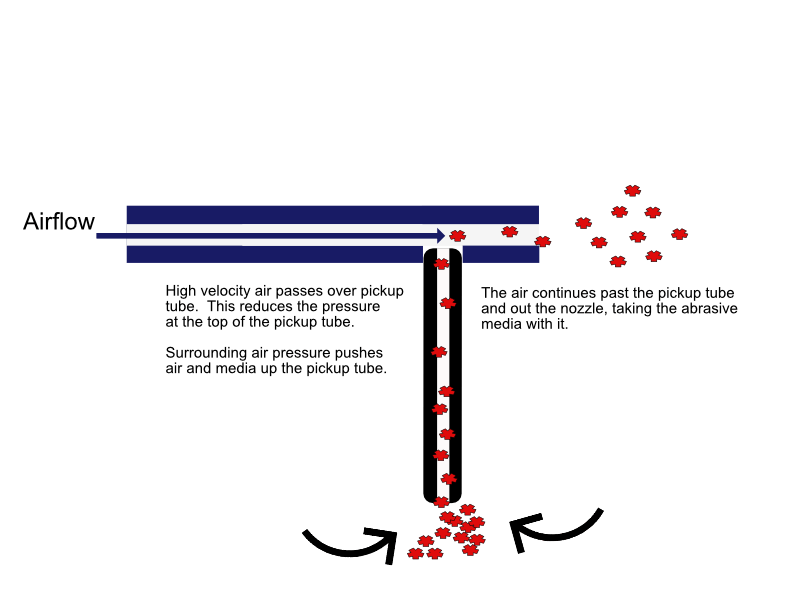

Suction guns are generally made use of in short-run or light manufacturing, maintenance, as well as remote field applications. The much less hostile nature of suction or siphon guns increases the moment to strip or clean components. On the benefit, the lower aggressiveness reduces the see here now wear rate of the parts within a suction gun. Suction gun components often tend to last longer minimizing blast tools upkeep costs.

The 8-Minute Rule for Pressure Washer Sandblaster

Detergents can be contributed to the water to loosen up deposits, dissolve oils or oils and also increase the cleansing process. sand blaster for sale. Corrosion preventing agents can be included in the water to avoid rusting of damp steel after the blasting procedure is total. If rust suppressors are not contributed to the water, go to this web-site then the steel must be dried, fueled oil, or repainted after blasting to avoid rust development.They suppress 50% to 85% of the dust produced. The water ring or halo nozzles provide less dirt control than the water induction or injection nozzles. One disadvantage of slurry blasters is tidying up the muddy mess created in field applications. Slurry blast tools is exhausting for operators to bring and also manage since a heavy water hose pipe is affixed.

Vapor rough blast systems supply the greatest degree of dirt reductions, up to 95%. The rough slurry takes a trip through a blast pipe to the slurry blasting nozzle.

The Only Guide to Harbor Freight Sand Blaster

Ice blasting cabinets need to be created to manage the cooler media, along with the condensation on lines, cabinet walls, pots, and also vessels. The products of building and construction can not consist of sorts of plastics or metals, which come to be weak at reduced temperatures. Dry ice is gentler and also softer than plastic media. Solidified carbon dioxide media can be in 2 types: pellet and also shaved or snow-like flakes.Preferably, the media and also dirt produced from blasting parts is contained within the cupboard and also purification system. Blast cabinets create leaks as seals put on as well as tear over time.

Securing permits the components to be much more easily gotten rid of for cleaning, fixing, as well as replacement. Bonded blast cupboards have a tendency to be extra airtight with less leak of blast media and also dust right into the shop, but replacement of used cabinet sides or bottoms is challenging. The unpleasant blast stream wears all-time low and sides of the cupboard in time.

The Single Strategy To Use For Sandblasting Near Me

What Are Blast Closet Materials of Building? Blast closets for completely dry or air blasting are made of steel with powder finishings or commercial paint. Wet blasting cabinets are made of even more corrosion-resistant products such as stainless steel. In particular completely dry blowing up applications such as medical instruments and clinical implants, stainless steel building and construction materials could be made use of to prevent iron contamination of a surface area.Steel elements or steel shot impacting stainless steel components can transfer metal to the stainless surface area, which can modify passivation and also lead to rust on the surface area. Wear-resistant steel liners are tactically put within blast chambers to reduce wear of the blast device (shot blasting near me). Wear-resistant alloys consist of manganese steels such as Manganal and also their website nickel as well as chromium white actors irons such as Ni-Hard alloys.

Report this wiki page